Download Technical Specification Here:

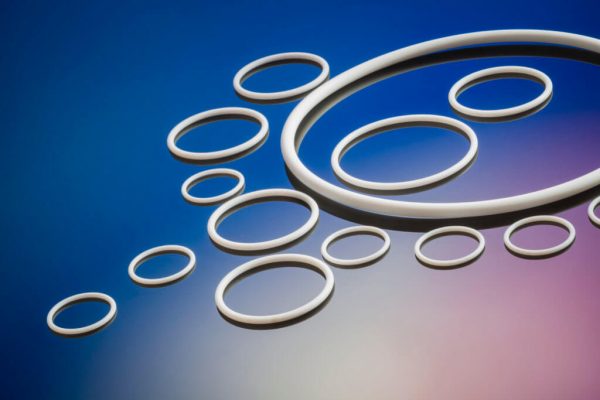

PTFE / Teflon / FEP O-Ring

PTFE exhibits some unique properties when used in O-Ring sealing systems.

The most well known is its impervious nature to virtually all fluids and gases from -320 °F to +450 °F.

Only molten alkaline metals and certain halogenated compounds will degrade its integrity. There are no elastomeric compounds in our PTFE products.

PTFE O-Rings do not have the compliance of rubber O-rings. To ease assembly, the crosssectional squeeze should be reduced relative to that specified for rubber.

PTFE O-Rings generally are not subject to spiral failure as are rubber O-Rings, so gland width can be reduced.

If you are concerned about the compatibility of your O-Ring seal with a sealed medium, or sealing over a wide temperature range, PTFE is one of the safest choices you can make.

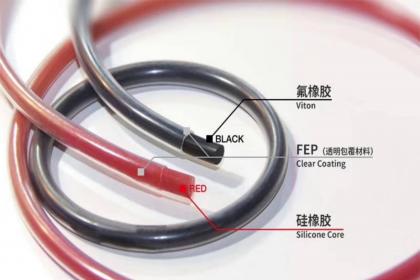

An Encapsulated ‘O’-Ring is an ‘O’-Ring bound by a seamless and uniform FEP/PFA encapsulation, which encloses an elastomeric core, completely protecting it from the media. They combine the energising properties of an elastomeric ‘O’-Ring with the resilience to extreme temperatures and hostile chemicals of FEP/PFA.